THE BUILDS

PETER HANDLEY PHOTO

Vintage Wings of Canada not only keeps alive the memory of those airmen and airwomen who have gone before us—their aircraft and their stories—but also the skills, techniques and tools to maintain, restore and even build these extraordinary machines from scratch. Our experienced and motivated engineers work their magic on the metal, fabric, systems and power plants to turn out restored aircraft that are second to none. The Roseland Spitfire (Y2-K), the only aircraft of its type to be built from scratch in Canada, recently won the coveted Reserve Grand Champion Award (The Silver Lindy) when it appeared at Oshkosh in 2018 as well as a Phoenix Award and a Golden Wrench, the Michelin Star for mechanics. The Phoenix Award is given to the recognize the “highest achievement in craftsmanship and dedication in the preservation of aviation history accomplished in restoration.”

Now, the McKnight Hurricane XII is ready for its first test flight after a nearly 15-year re-build and will no doubt take the warbird world by storm. The rebuild of the Fairchild Cornell and National Steel Car Westland Lysander was was accomplished in large part using the help of volunteers under the direction of the Vintech Aero team of professionals. To achieve such excellent results and engage people in such an educational and social project only helps to build a wider interest in the operation and care of vintage aircraft, thus helping to honour our citizens who fought and continue to fight for our Canadian values.

The Roseland Spitfire Photo: Peter Handley

The McKnight Hurricane. Photo: Peter Handley

The Andy Carswell Lysander. Photo: Peter Handley

Hawk One F-86 Sabre. Photo: Peter Handley

The Archie Pennie Cornell. Photo: Peter Handley

The Willie McKnight

HAWKER HURRICANE XII

PAT TENGER VIDEO

Battle of Britain Hurricane pilot Flying Officer William Lidstone “Willie” McKnight is a legend in England yet scarcely known in Canada, even in his home town of Calgary. McKnight was a fighter pilot in the Battle of France and the Battle of Britain with 242 (Canadian) Squadron of the RAF.

By the time of his disappearance in action in January of 1941, his score was 18 Luftwaffe fighters and bombers and two Distinguished Flying Crosses. By building this aircraft in his name, we bring his story to life for generations to come.

In 2007, Mike Potter purchased a restored Canadian Car and Foundry-built Hawker Hurricane Mk XII from Assiniboia, Saskatchewan farmer, pilot and AME Harry Whereatt. Whereatt was a legend in the early years of historic aircraft recovery and restoration in Canada, having purchased relic fuselages, wings and engines for, among other types, Canadian-built Lysanders and Hurricanes and stored them on his South Saskatchewan farm. The Hurricane XII (RCAF Serial Number 5447 C/N 46002) was a project that Harry had been working on for decades and had been flown by him on one occasion, so was sold as an aircraft on flying condition.

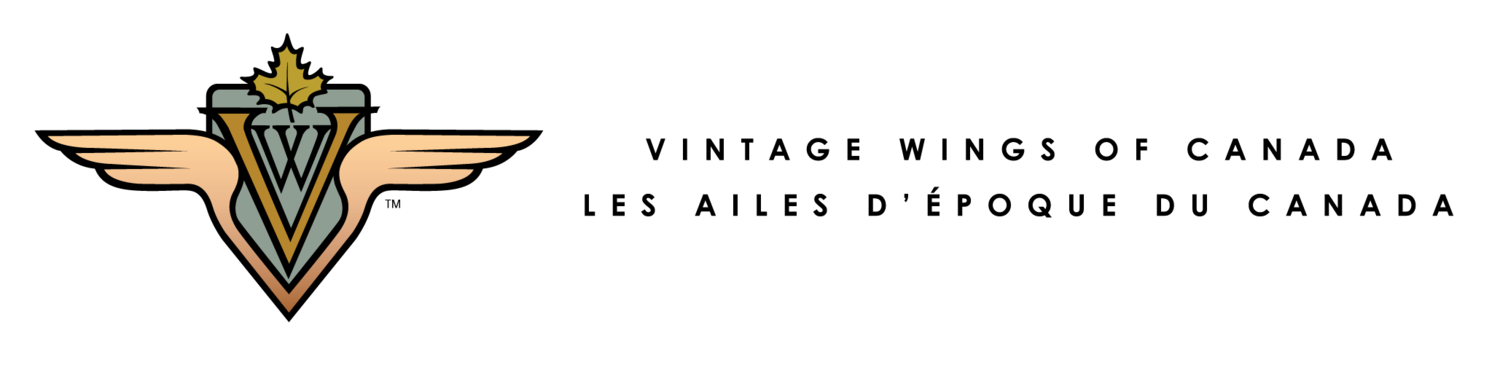

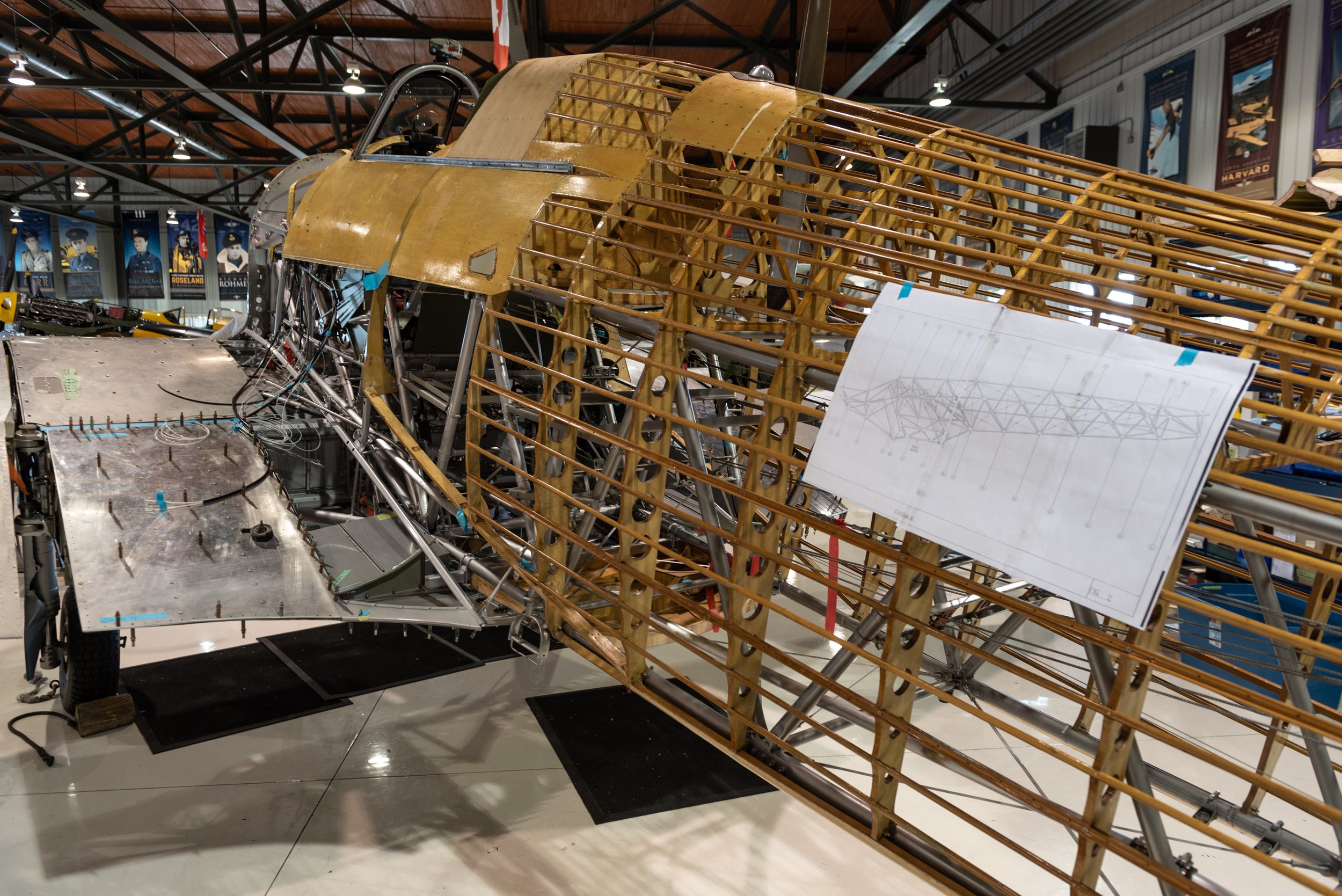

After its arrival at the Vintage Wings facility in Gatineau, Québec, the Hurricane was stripped of it skin for inspection and its wings were sent to a Southern Ontario shop for some work on fuel tanks. In order to ensure a solid paperwork trail, It was decided to take the aircraft down and start over, including an all-new wing centre section which required the building of a massive jig to guarantee alignment. Early work on the project included some supervised time put in by volunteers, keeping the project moving along slowly.

Unlike the all-metal Spitfire, the Hurricane’s structure includes some wood components in the fuselage, requiring not only skills in metal-working but also cabinet making. A considerable portion of that was the excellent work of Harry Whereatt.

Early on, it was decided to paint the restored Hurricane in the unique and very distinctive markings of a Hurricane I (Serial No. P2961) flown by Willie McKnight a Canadian pilot in the RAF. The squadron nose art included a cheeky depiction of Hitler being booted in the ass by a black flying boot with 242 written on it. But more strikingly, the side of the fuselage carried a large representation of a skeletal grim reaper with a sickle in hand pointing forward to the enemy he is about to claim. It is widely held that McKnight, a former pre-med student at the University of Alberta, was the artist who did the design.

Work on the restoration took many years as the Vintech team focused on other projects such as the Roseland Spitfire. After the completion of the Spit, Vintech returned to the Hurricane project with gusto, and the aircraft was ready for the paint booth. Considerable research and effort was expended getting the aircraft’s paint colours and markings right. In doing so we were able to show that all previous guesses by modellers and artists as to the size of the roundel and fin flashes were likely incorrect.

Once painted engine tests and high-speed taxi tests proceeded in the summer of 2021 with first flights possible in late fall.

Some of the people in the restoration of the McKnight Hurricane. Left to right: Dave O'Malley (research and markings), Paul Tremblay (Director of Maintenance, Vintech Aero); Ken Wood, Structures and Metals; Mike Potter, Funder and Founder; Laurent Palmer, AME; Jim Luffman, Volunteer technician. On wing: André Laviolette, AME; Pat Tenger, AME and Hurricane Project lead.

Harry Whereatt completes engine test on the Hurricane in Assiniboia. Via Whereatt Family

Harry and Anna Whereatt on the their Assininboia farm with the Hurricane in 1993 during a visit by the Canadian Aviation Historical Society. Photo from Angie McNulty

The Hurricane arrives from Saskatchewan, 2006. Vintage Wings Photo

The Hurricane arrives from Saskatchewan, 2006. Vintage Wings Photo

The Hurricane arrives from Saskatchewan, 2006. Vintage Wings Photo

Warwick Patterson Photo

The Hurricane IV's centre section undergoing restoration in the purpose-built jig. Richard Mallory Allnutt Photo

Patrick Rossiter Photo

Pat Tenger Photo

Patrick Rossiter Photo

The skeletal fuselage and empennage on display at an air show at Gatineau. Pierre Langlois Photo

Dave O'Malley Photo

Peter Handley Photo

Peter Handley Photo

Warwick Patterson Photo

Peter Handley Photo

Peter Handley Photo

Pat Tenger Photo

Peter Handley Photo

Peter Handley Photo

Peter Handley Photo

Pat Tenger Photo

Peter Handley Photo

Dave O'Malley Photo

Peter Handley Photo

Pat Tenger Photo

Pat Tenger Photo

Pre-completion Engine Run-up. Pat Tenger Photo

Pre-completion Engine Run-up. André Laviolette Photo

Pre-completion Engine Run-up. André Laviolette Photo

Pat Tenger Photo

Peter Handley Photo

Peter Handley Photo

Peter Handley Photo

Peter Handley Photo

Peter Handley Photo

Peter Handley Photo

Peter Handley Photo

Peter Handley Photo

Peter Handley Photo

Dave O'Malley Photo

Pat Tenger Photo

Pat Tenger Photo

Peter Handley Photo

Peter Handley Photo

The Archie Pennie

FAIRCHILD CORNELL

PETER HANDLEY PHOTO

Building a Yellow Wings classic and paying tribute to the British Commonwealth Air Training Plan and one of its dedicated instructors — Flight Lieutenant Archie Pennie

To complete the Yellow Wings line-up of single engine training aircraft, Mike Potter purchased a Fairchild Cornell in 2010 to complement the North American Harvard, de Havilland Tiger Moth and Fleet Finch already in the hangar. The Fleet Cornell would also enhance Vintage Wings Sponsored Ride program by offering a trainer aircraft that has more tolerance to stronger crosswinds unlike the Tiger Moth and Finch that are often restricted low cross-wind days and can often be limited in flight opportunities throughout the flying season.

Vintage Wings took possession of the aircraft in February 2010 and brought it to Gatineau via road delivery in a sea-container. With a complete “spinner to rudder” rebuild necessary, the long and detailed restoration process began the following spring. The completion was earmarked for the spring of 2011 leaving only one year to completely refurbish the Cornell from the ground up.

In the business of aviation restoration, the correct approach is a combination of reviewing all available drawings and blueprints coupled with reverse engineering to fill in the voids where past skills and knowledge are no longer maintained. This process involves a close examination of the structure of the parts and how they function and perform. The purpose is to determine how a structure is designed from the final product when little to no knowledge about the procedures involved in the production of the original is available.

The Cornell’s wings are of an all-wood construction and for safety reasons, the wings and centre section were stripped down, inspected and rebuilt as was the entire fuselage. Much of this work was done by volunteers (some with no experience in aircraft restoration) under the careful supervision of Vintech Aero maintenance engineers. Using volunteer labour allowed the restoration work to continue apace and the aircraft was finished in time to join the other Yellow Wings aircraft in a tour of Western Canada and appearances at Oshkosh’s AirVenture 2011.

Restoration processes as involved as this proved that Vintage Wings was capable of culminating all the outside expertise and practices and adapting for in-house techniques that save time and expense. More importantly, it demonstrates a level of professionalism and skill characteristic of many large aviation refurbishment businesses.

The Arnold Roseland

SUPERMARINE SPITFIRE

PETER HANDLEY PHOTO

From a pile of corroded steel piping and aluminum skins in a South African junkyard, it’s a long road to the beautiful Roseland Spitfire, the only Spitfire ever constructed from scratch in Canada — winner of Reserve Grand Champion, a Phoenix Award and a Golden Wrench award at Oshkosh 2018. The Phoenix award is given to recognize the highest achievement in craftsmanship and dedication in the preservation of aviation history accomplished in restoration, while the Golden Wrench Award is like a Michelin Star for aircraft engineers.

Supermarine Spitfire Mk IX, RAF serial number TE294 – Twenty years ago, nothing more than a pile of rotting metal and loose components, TE294 had almost been subsumed by the earth from which she came—her aluminum and steel structure corroding and breaking down in a scrapyard in South Africa, her wings long gone, component parts stolen or vandalized.

Only to someone who could recognize her broken, twisted and rusted bones was she still a Spitfire. In the 1990s, TE294 was rescued, the decline to dust arrested, and the long, long journey to living warbird commenced.

From South Africa, her boxed bones travelled to British Columbia, Canada, where a group of passionate volunteers at the Comox Air Force Museum took on her daunting rebuild as a millennium project and as an homage to the wartime pilots of 442 Squadron, a Search and Rescue squadron of the Royal Canadian Air Force still residing on the flight line at 19 Wing, Comox.

In 2000, the Comox Air Force Museum, with a grant from the Y2K Millennium Fund, purchased TE 294 and embarked on the Y2K Spitfire Project. The project was funded entirely by donations and grants from the general public and the restoration proceeded slowly. For a number of years, the Comox team made steady progress, but continued funding of the extremely expensive enterprise became problematic.

In order to keep the Spitfire in Canada and continue the restoration here, Mike Potter and Vintage Wings of Canada took over the project and invested several million dollars to bring the project to completion. The fuselage would continue being built in Comox, but by skilled engineers who worked for Vintage Wings. The wings, which had previously been sent to a builder in Great Britain were in deplorable shape and had to be brought back to Gatineau where they were essentially started over.

In 2014, the Vintech team in Comox shipped the fuselage project to Gatineau where Vintech Gatineau engineers would complete the work and marry it to the wings. The wings project was carried out by aircraft structures expert Ken Wood. By 2017, the project was finished and The Roseland Spitfire completed her test regime.

When the volunteers at the Comox Air Force Museum began work on TE294, they went forward under the hopeful banner “She will fly again.” Vintech Aero and Vintage Wings of Canada have always respected this vision of the project’s founders and we are proud to have helped fulfill that promise they made.

In 2018, the Roseland Spitfire completed a 5,000 mile return trip to Comox where she was flown for the volunteers to see and hear. On her way out, she stopped at Oshkosh for a few flying demonstrations and won several awards in the warbird category including Reserve Grand Champion, a Phoenix Award and a Golden Wrench award at Oshkosh 2018. The Phoenix award is given to recognize the highest achievement in craftsmanship and dedication in the preservation of aviation history accomplished in restoration, while the Golden Wrench Award is like a Michelin Star for aircraft engineers.

Possibly a Mark de Vries photo

Dave O'Malley Photo

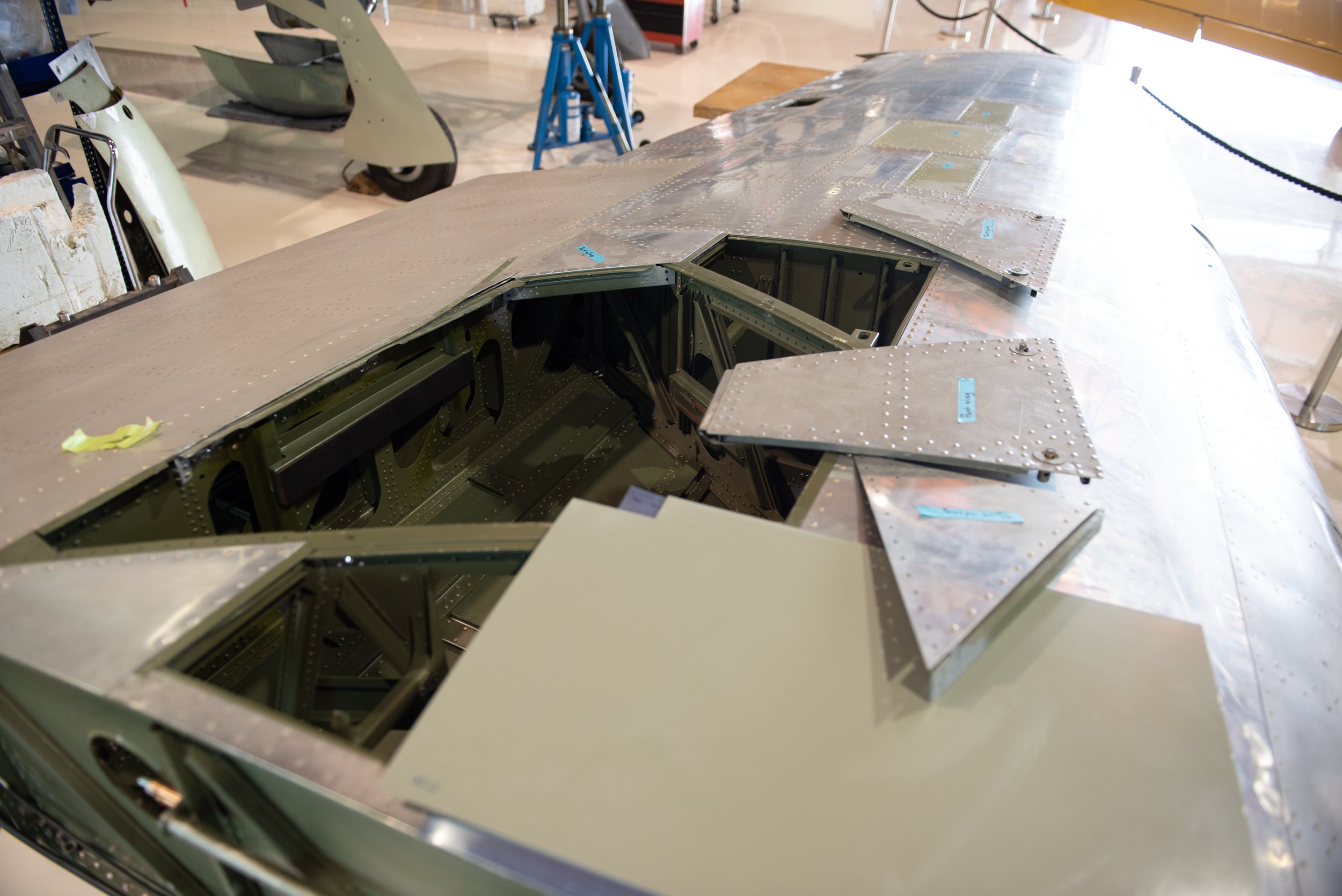

The multi-dimensional complexities of building a Spitfire in the Castle Bromwich factory during the Second World War were overcome by jigs, custom tools, forms, molds, templates and thousands of employees. To build Spitfire wings, controls and fuselage components in Canada in the Third Millennium—70 years after the factories were closed—took some ingenuity on the part of Wood. In many cases, he needed to first build tools that would enable him to build the parts or to form three-dimensional magic in metal—tools like the “Fuel Bay Sumptuator”, “Wing-Rib Former 2000 Max”, “Fairey Fastener Locator”, and the world-famous “Bearing Dust Seal Flangetron” (patents pending). Photo: Ken Wood

Dave O'Malley Photo

Topside wings skins are about to go in the starboard wing. Dave O'Malley Photo

Dave O'Malley Photo

Dave O'Malley Photo

Lead structures engineer on the Roseland Spitfire, Ken Wood preps the aluminum skin panel for the port side engine cowling. Photo: Peter Handley

Dave O'Malley Photo

Dave O'Malley Photo

Beneath those extraordinarily sublime and elegantly simple elliptical Spitfire wings ran a labyrinth of ribs, supports, straps, wells, access panels, bays, channels, spars and linkages—held in place by thousands of rivets, each part with specific requirements for gauge, strength and hardness of material. Ken Wood’s methodical and unhurried pace ensured that mistakes did not build upon each other, rendering weeks, months or even years of work scrap. To be in the company of Wood near his wing build throughout this period was to be in a sort of Zen-like zone where voices were lowered, decisions were made only after checks were made and remade, and where craftsmanship and quality of work became a fetish. Photo: Ken Wood from GoPro

Peter Handley Photo

The gang from Comox was on hand to see the work. Left to right. Ken Hazell, Dean Sept, Ken Wood and Ian ward. With work on the fuselage and engine progressing nicely, Sept will make a few trips to Gatineau over the next year to help Wood who has single-handedly done all the wing work so far. Peter Handley Photo

Peter Handley Photo

Dave O'Malley Photo

The craftsmanship is extraordinary. Dave O'Malley Photo

The starboard engine cowling panel is now fully shaped and perfectly fitted, ready for riveting to its underlying structure. Photo: Peter Handley

Peter Handley Photo

Peter Handley Photo

Peter Handley Photo

Peter Handley Photo

Ken Wood begins the complex structural work on the Spitfire’s elevator. Photo: Dave O’Malley

Everything from tiny components to structural assemblies had a fresh coat of paint. Dave O'Malley Photo

Last year, with the major components completed, Wood began work on the wing tips—a combination of cabinet-work and extreme sheet metal work. The Spitfire’s wing tip structure was made from wood to save vital war materials, then covered with aluminum. Photo: Ken Wood

Dave O'Malley Photo

Dave O'Malley Photo

Ken Wood (left) and mechanic Pat Tenger place the top cowling panel over the engine bay to assess work needed to create the perfect fit. At this point the cowling panels lack structural integrity and need further shaping and trimming before being backed by structural stiffeners. Photo: Peter Handley

Wood contemplates his next step as he fits the port engine cowling to the Spitfire’s frame. As beautiful as the polished aluminum is, her final coats of primer and camouflage paint will tell a Canadian story of heroism that will outshine anything. Photo: Peter Handley

Never hurried, Wood contemplates his next move when re-attaching the Spitfire’s propeller. More than half a year ago, the Spit was towed outside and its big Rolls-Royce Merlin was ground run—twice. Photo: Peter Handley

Vintech West Photo

Roseland's great grandson Aiden takes a peek at the finished cockpit. Peter Handley photo

Peter Handley Photo

A detail of the markings on TE294 as 442 Squadron Spitfire IX MK304. It was at this time that I discovered the mistakes made in previous Y2-K provenance. Painting the Spitfire involved many other types of markings such as W/T Wire Terminus stencils, Technical Directorate paint type stencils (Cellulose and Synthetic), and factory/Civilian Repair Organization contract stencils—all of this so complex, detailed and interesting to a geek like me, but far too complicated to explain here. Suffice it to say that the complex numerical stencils one sees on Second World War RAF aircraft are UNIQUE to each aircraft and cannot be simply copied from a previous aircraft—long story for another day. Photo: Dave O’Malley

It takes a village to raise a Spitfire. Some of the mechanics involved today with the Roseland Spitfire project: (standing left to right): Pat Tenger, Ken Wood, Mark Dufresne, Gerry Bettridge. At right is Mike Irvin, who has just joined Vintech Aero. Taking a knee: André Laviolette and Paul Tremblay. Photo: Dave O’Malley

Peter Handley Photo

Peter Handley Photo

The Roseland Spitfire restoration earned Vintech Aero, its builders, a Golden Wrench award from the Experimental Aircraft Association at Oshkosh's Airventure in 2018

The Andy Carswell

Westland Lysander

PETER HANDLEY PHOTO

Vintech Aero took a Canadian-built Lysander project started by Saskatchewan warbird legend Harry Whereatt down to the bones and rebuilt it as a tribute to Canada’s nascent aerospace industry.

The Andy Carswell Lysander is owned and operated by Lysander Funds and is based most of the year in Edenvale, Ontario. It was originally assembled from major components of a number of salvaged Canadian-built RCAF Lysanders by the legendary Harry Whereatt in Assiniboia, Saskatchewan.

When the Lysander arrived by truck in 2008, it was painted in the striking “Oxydol” paint scheme used by target tugs at bombing and gunnery schools of the British Commonwealth Air Training Plan in Canada during the Second World War. In order to inspect the structure and restore the aircraft all fuselage, empennage and wing skins were stripped away. The engine was sent to Great Britain for overhaul while a group of both novice and technically experienced volunteers under the supervision of Vintech professionals began taking the airframe apart and learning new skills such as aircraft fabric rib-stitching and wood working.

The volunteer labour experiment worked very well and progress was rapid. Within two years, the Lysander was ready for her new paint scheme — this one chosen to represent the very first Canadian-built example to come off the National Steel Car assembly line at the beginning of the Second World War.

Following its test flights, the Lysander was dedicated in 2010 to a Prince Edward Islander by the name of Cliff Stewart, who as an army intelligence operative (spy) with British security Coordination and who was dropped off behind enemy lines several times by a Lysander landing in an unprepared field in the dark.

In 2015, the Lysander was sponsored by an investment group known as Lysander Funds and began touring airshows and fly-in events throughout Southern Ontario. The founder fo Lysander Funds, John Carswell, a strong champion of veterans issues and wellbeing, supported the program to honour his father Andy, a former Lancaster and Canso pilot and PoW.

On 2019, Lysander funs purchased the Lysander which will continue to support Vintage wings of Canada events during the flying season. The Lysander now has a second honouree — Squadron Leader Andy Carswell, AFC, CD.

Way back in the 1970s, the Lysander is seen in the hangar of legendary Harry Whereatt -the Obi-Wan Kanobe of Canadian aircraft restoration. Harry was personally responsible for saving some of our most cherished aviation artifacts. Whereatt (and his family) would work tirelessly for decades to build the Lysander from the remains of three Lysanders. Photo via Bill Ewing

In Harry Whereatt's hangar in Assinaboia, the Lysander nears completion in 1993. Whereatt chose to paint the Lysander as a Target Tug for the British Commonwealth Air Training Plan. Photo via Bill Ewing

The first engine run in July of 1996. With harry at the controls, her Bristol Mercury engine coughs into life with a farm pick-up truck providing the power to crank. Despite a successful engine start, the Lysander never flew - qualified Lysander pilots being in short supply. Photo via Bill Ewing

Don't worry Harry, we'll take good care of her. A somewhat wistful Whereatt plays along for a photo-op at the time (May, 2007) that we picked his Lysander up in Saskatchewan. Photo by John Brennan

Our new Lizzie arrives in Gatineau, May 28th, 2007. Upon her arrival she was put into storage for more than two years with her engine going to England for overhaul. Photo by Mike Henniger

Volunteer power was critical to the speedy restoration of the Lysander - here VWC pilot Blake Reid (foreground) and Ted Devey prepare the Lysander's access panels to receive a new fabric covering. The airframe on the left is our Hawker Hurricane XII project. Photo: Peter Handley

Tall and quirky beyond description, the Lysander was not an easy aircraft to work in and around. Photo: Peter Handley

Peter Handley Photo

The Westland Lysander is a big aircraft, with a large engine compartment. We see the accessory bay here, shortly before the freshly overhauled Bristol Mercury was remounted on the airframe. Richard Mallory Allnutt Photo

One of Vintage Wings technicians works on re-skinning the Lysander's horizontal stabilizer. Richard Mallory Allnutt Photo

Volunteers hoist and attach the port wing. Peter Handley Photo

Young Christian Brunelle, now a 412 Squadron pilot, secures the tip on the port wing during installation. Peter Handley photo

It was a big occasion indeed when her Bristol Mercury was finally re-attached - Photo: Peter Handley

Peter Handley Photo

Peter Handley Photo

Deryck Hickox teaches proper rib stitching techniques to Vintage Wings volunteers. Peter Handley Photo

Peter Handley Photo

Restoration lead Deryck Hickox (left) with founder Mike Potter and the three members of the Brunelle family who volunteered to work on the Lysander. Peter Handley Photo

Peter Handley Photo

Peter Handley Photo

Peter Handley Photo

The Lysander restoration team poses with their project prior to recovering. Front Row: Allan Macmillan, Jim Ashby, Jim McGregor, Ted Devy, Renaud Gagne, Steve McKenzie, Deryck Hickox, Rob Fleck Back Row: Jim Luffman, Nelson Smith, John Aitken, Bob Boyer, Wayne Giles, Terry Cooper Photo: Peter Handley

The Westland Lysander, and her wings, before they were completed, and the fabric changed in mid-2009. Richard Mallory Allnutt Photo

This is just one of many highly complex welded joints on the Westland Lysander. Richard Mallory Allnutt Photo

The Vintage Wings Lysander as she looked last December with freshly doped fabric. Her wings are already painted silver, in the markings of the prototype Canadian-built example, which first flew on 16th August, 1939 at the hands of E. Leigh Capriol. Rob Erdos will take the Lizzie up on her first post-restoration flight, much like he did with the Canadian Warplane Heritage example in 2009. Richard Mallory Allnutt Photo

Peter Handley Photo

HAWK ONE

PETER HANDLEY PHOTO

Vintage Wings of Canada bought an aging Canadian-built Cold War jet and within 18 months turned her into a dazzling gold airshow star in 2009 to help Canada celebrate the centennial of powered flight in Canada.

On February 23rd, 1909 J.A.D. McCurdy made Canadian history at Baddeck, Nova Scotia as the first Canadian to fly a powered heavier-than-air aircraft in Canada. Just fifty years later in 1959, the Royal Canadian Air Force celebrated that achievement by creating the all-jet aerobatic team known as the Golden Hawks (for the golden anniversary). In 2007, Vintage Wings acquired a similar F-86 fighter jet and began restoring it to military spec so that we could fly it in front of Canadians from coast to coast in 2009, the 100th anniversary of McCurdy’s flight.

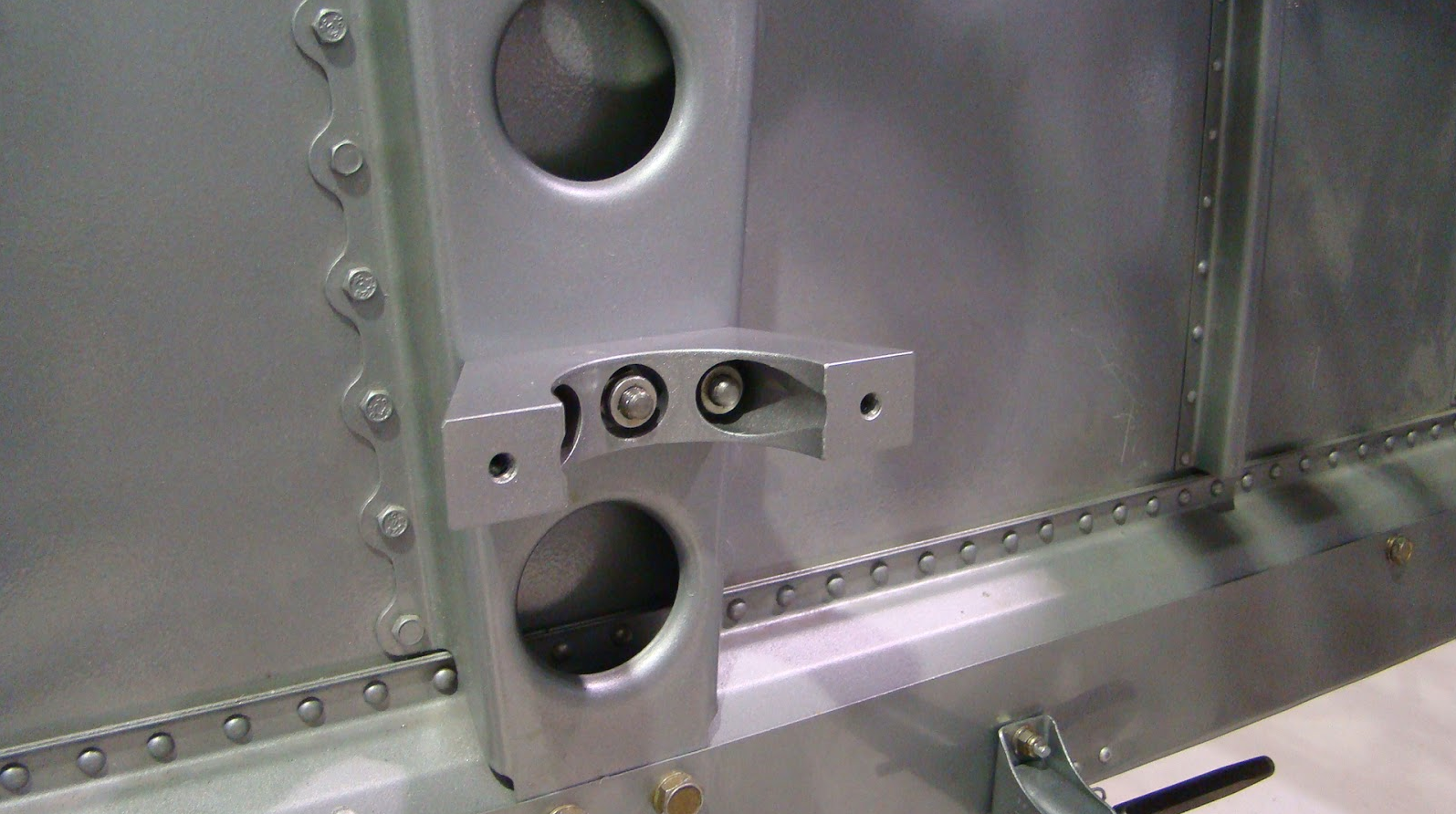

Restoration began immediately after the F-86 (a former Golden Hawk try-out aircraft) was ferried to Gatineau. The Orenda engine was removed and sent to Magellan Aerospace for overhaul. All the systems were inspected and torn down. The cockpit instrumentation was updated and an RCAF ejection seat was installed.

The sabre is taken apart at Gatineau in 2007 shortly after its ferry flight. Warwick Patterson Photo

Warwick Patterson Photo

Warwick Patterson Photo

Test pilot Paul Kissmann during engine tests. Peter Handley Photo

Peter Handley Photo

Robert Sullivan Photo

Warwick Patterson Photo

Robert Sullivan Photo

Test pilot Paul Kissmann performs a engine run-up at Gatineau airport. Robert Sullivan Photo

Engine tests. Robert Sullivan photo

Peter Handley Photo

Peter Handley Photo

Engine start during first test flight. Peter Handley Photo

Hawk One takes off for first post-restoration flight. A few weeks later, it headed to Cold Lake, Alberta for a new golden Hawks commemorative paint scheme applied by the RCAF. Peter Handley Photo

Peter Handley Photo

Peter Handley Photo

Peter Handley Photo

520 knots baby! Paul Kissmann is jubilant after the successful first flight. As the designer/applicator of the vinyl decals Hawk One was wearing, Dave O'Malley was jubilant that they were still attached after reaching speeds of 960 kph.! Peter Handley Photo

Photo: Cpl. Jennifer Chiasson, AETE.